Know your opportunities with 3D printing

Manufacturing processes are drastically changing since the 18th century, starting with the first and the second industrial revolution, that enabled mass production using water or steam power and lastly electricity. The third revolution enabled automated processes and led to big changes in our everyday life, using new information technologies like the computer.

In the last few years, people speak of a 4th revolution in the market, also called Industry 4.0. This revolution is transforming manufacturing processes in a new way by building “digital factories”. Smart technologies automate and connect all processes. One of those applications changing the way of manufacturing today is additive manufacturing, also called 3D printing. However, what is this relatively new technology and what are the benefits it offers? Here is all you need to know about it!

What is additive manufacturing?

To start with, additive manufacturing is the opposite of subtractive, also called traditional, manufacturing. In subtractive manufacturing usually a block or raw material is the starting point. The part is formed by cutting down the raw material, e. g. with a CNC machine.

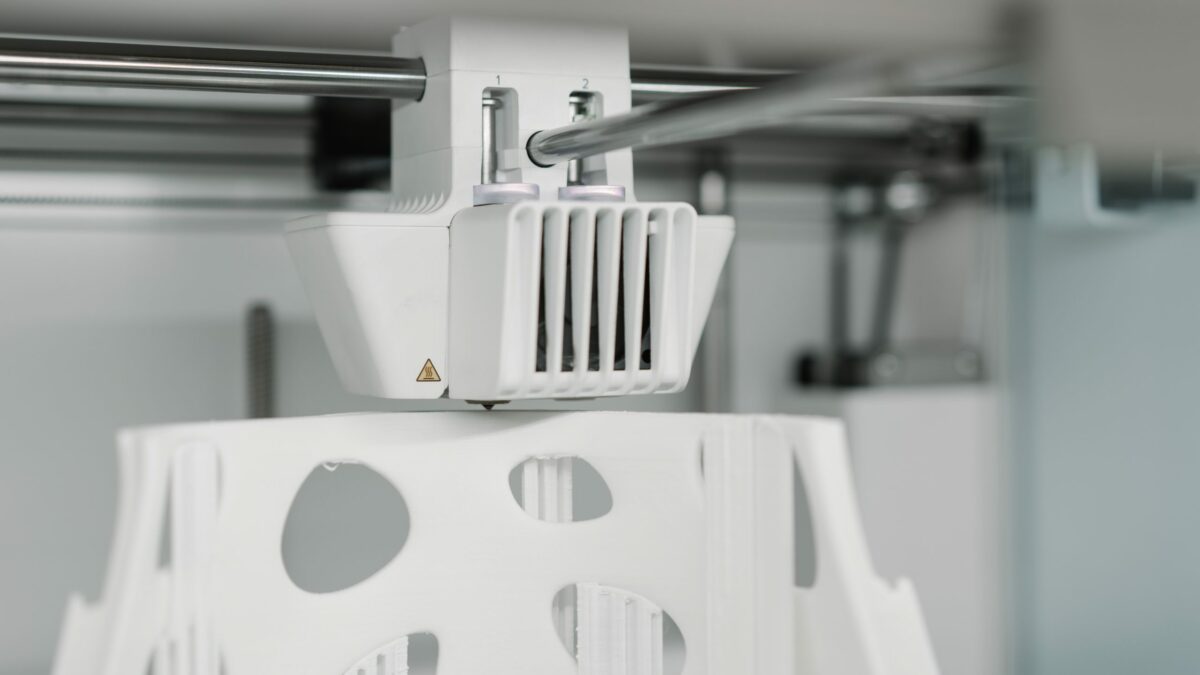

In additive manufacturing, however, the process starts with a blank build tray. A printer is building up a three-dimensional object one layer at a time, thus saving a lot of material compared to traditional processes. The information about form, color and texture is usually saved in CAD or another 3D modeling software and the process is automated. Parts can be printed in almost any complex geometry and a lot of different materials, like polymers and metals.

There are multiple 3D printing technologies, from simple ones to more complicated ones. All different 3D printing technologies have their own benefits and limitations and ability to use different materials. The most used and probably simplest 3D printing technology is Fused Deposition Modeling (FDM). FDM is when a material (called a filament) is being dispensed through a nozzle according to a specific pattern creating an object.

What opportunities does additive manufacturing offer?

Enough of the technological side, let’s talk about the most interesting part now - why is additive manufacturing used in the industries? Here are the top opportunities, that it offers:

1. From mass production to mass customization

As mentioned earlier, the 2nd and 3rd industrial revolution brought mass production and automated production. But this is not what customers want anymore. The trend goes to tailor-made products, that fulfill the customers special needs and wishes. In traditional manufacturing, this is not possible, as huge set-up costs and logistical effort make individualized products uneconomical. This is where 3D printing comes in. 3D printing offers the ability to produce customized and even complex products without high production and logistical costs, as one printer can print an infinite number of different products on-demand. While in traditional manufacturing high fixed costs are a huge challenge, using 3D printing those costs are turned into variable costs, as they only occur when a part is actually ordered.

2. Decentralized production

3D printing also solves the problem of central production and warehousing, that lead to huge logistical effort and higher supply chain risks. With additive manufacturing the production can be closer to market. Currently, big plants are needed for the production of goods. To keep the costs of these production plants low they are often placed in remote countries with more affordable resources. With 3D printing these big plants are not necessary anymore and production can be done closer to or even at the place where the product is actually consumed. This leads to lower production times, lower logistics costs and it would reduce the carbon footprint drastically.

3. Production of small batch sizes

Usually, it is not economically viable to produce one single part with traditional manufacturing. However, when just a single product, such as a rare spare part, has been ordered, this could be requested. In normal production set-up costs for building up a production would be immense, why production is usually done in batches. Everything that is not needed will go into storage. With 3D printing, set-up costs for small batch sizes are reduced to a minimum, and parts can be produced starting from lot size 1.

4. Rapid prototyping and fast go-to-market

The time between design and production rapidly sinks with the use of additive manufacturing. Ideas can be developed using a CAD software and produced with additive manufacturing within days instead of several weeks. A production set-up and building a mold, for instance, is not necessary, which shrinks the costs to a minimum. Also, innovation within companies, can increase. After evaluating the 3D printed prototype, the products are ready to go to the market. Here, for example, they can easily be tested for customer acceptance, as small batch sizes are possible with 3D printing.

These are just some of many opportunities additive manufacturing offers, and the specific use case has to be evaluated individually for companies. Each industry has its own characteristics and benefits in a different way from 3D printing. If you want to find out how additive manufacturing is used today and what we can expect from it in the future, stay tuned for our next blog!

If you have any comments, feedback or questions, drop us a note on: info@replique.io.

Categories

- 3D printing industries (5)

- Basics (3)

- News (1)

- Point of View (7)

- Press (16)

- Press (16)

- Sustainability (3)

- Technology (5)

- Uncategorized (1)

- White Paper (1)